Grinding And Polishing Expertise: How To Grind A Mirror Surface?2022-04-25

Grinding is basically unidirectional cutting, and it is more difficult to achieve a mirror surface. The more commonly used method is to use free abrasives for multi-directional grinding to achieve mirror surface results. However, the free abrasive polishing method is prone to problems such as too long processing time and difficulty in maintaining dimensional accuracy, because the removal force of free abrasives is weak, and most of them use soft materials as auxiliary equipment, such as polishing pads or wool wheels.

So is it possible to directly use the grinding wheels on the grinding machine to achieve the result of mirror surface? And then take into account the dimensional accuracy, surface roughness and processing efficiency at the same time? In fact, it is feasible. While many factors play a role, the grinding wheel plays the most important one. In the selection of grinding wheels, the key points are the control of temperature and the maintenance of cutting force. Since it is mirror grinding, a finer-grained grinding wheel is usually selected. However, fine-grained grinding wheels usually represent insufficient cutting force and are prone to clogging. This can lead to burns, chapped, and even orange peel. If this is to be resolved, the grinding wheel is usually softened. However, if the soft grinding wheel consumes quickly, the dimensional accuracy is not easy to control.

Solution 1:

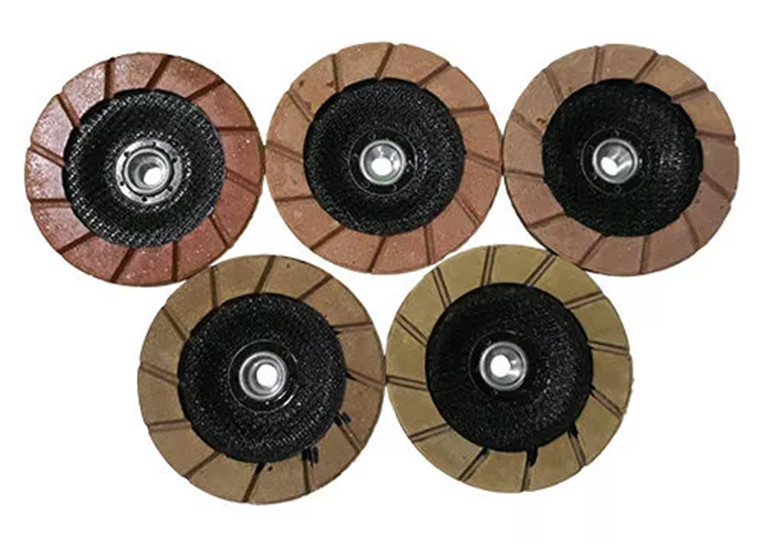

Use fine-grained diamond grinding wheels or CBN grinding wheels, but adjust and design enough air holes to solve the problems of easy blockage and difficult heat dissipation. Another thing to pay attention to is the inner disc of the grinding wheel and the heat dissipation effect of the inner disc.

In addition to the grinding wheel, it is also necessary to pay attention to the type of grinding fluid and filtration system, the rigidity and precision of the grinding machine, and the dressing and grinding conditions of the grinding wheel. Only by paying attention to all of the above variables can truly reproducible mirror grinding results be achieved.

Solution 2:

Use a relatively coarse-grained wheel, but with a resilient bond.

Due to the action of the elastic bonding agent, the coarser abrasive in the grinding wheel can be retreated to achieve a uniform grinding depth and further form the result of mirror grinding.

In addition to the grinding wheel, it is also necessary to pay attention to the type of grinding fluid and filtration system, the rigidity and precision of the grinding machine, and the dressing and grinding conditions of the grinding wheel. Only by paying attention to all of the above variables can truly reproducible mirror grinding results be achieved.

DTS Diamond Tools is a professional manufacturer of diamond tooling for concrete grinding and concrete polishing. We provide a wide range of diamond tooling for the popular grinding machines on the market such as HTC, Husqvarna, Scanmaskin, STI Prep/Master, Klindex, XPS, Terrco, Blastrac, Diamatic, Stonkor machines with lowest cost and most reliable quality. If you are looking for a solution to your concrete floor, we can provide you with professional advice and guidance.

- Company Info

- Feedback

- Customer Reviews

- About Us

- Contact Us

- Blog

- Help Center

- User Center

- Forget Password

- My Orders

- Tracking Order

- My Account

- Register