Abrasive Types2022-09-14

Abrasives are tools used for grinding,

lapping and polishing. Most of the abrasives are artificial abrasives made of

abrasives and binders, and there are also natural abrasives that are directly

processed from natural ore rocks. In addition to being widely used in machinery

manufacturing and other metal processing industries, abrasive tools are also

used in food processing, paper industry and processing of non-metallic

materials such as ceramics, glass, stone, plastic, rubber, and wood.

During the use of the abrasive tool, when

the abrasive grains are blunt, due to the partial fragmentation of the abrasive

grains themselves or the fracture of the binder, the abrasive grains partially

or completely fall off from the abrasive tool, and the abrasive on the working

surface of the abrasive tool continues to appear new cuts. Cutting edge, or

constantly expose new sharp abrasive particles, so that the abrasive tool can

maintain cutting performance for a certain period of time. This self-sharpening

of the abrasive tool is a prominent feature of the abrasive tool compared with

the general tool.

According to the source of raw materials,

abrasives can be divided into two categories: natural abrasives and artificial

abrasives. The natural abrasives commonly used in the machinery industry are

only whetstone. Artificial abrasives are classified according to their basic

shapes and structural characteristics, and there are five types of grinding

wheels, grinding heads, whetstones, sand tiles (collectively referred to as

bonded abrasives) and coated abrasives. In addition, it is customary to list

abrasives as a class of abrasives.

Bonded abrasives can be divided into

ordinary abrasive bonded abrasives and superhard abrasive bonded abrasives

according to the different abrasives used. The former is made of ordinary

abrasives such as corundum and silicon carbide, and the latter is made of

superhard abrasives such as diamond and cubic boron nitride. In addition, there

are some special varieties, such as sintered corundum abrasive tools.

Ordinary abrasive bonded abrasive tool is

an abrasive tool that is consolidated into a certain shape and has a certain

strength by a bonding agent. Generally composed of abrasive, bond and pores,

these three parts are often referred to as the three elements of bonded

abrasives.

Abrasives play a cutting role in abrasive

tools. Binder is a material that consolidates loose abrasives into abrasives,

and there are two types of inorganic and organic. Inorganic binders include

ceramics, rhombohedral and sodium silicate, etc.; organic binders include

resin, rubber and shellac. Among the most commonly used are ceramic, resin and

rubber binders.

The air holes play the role of chip

containment and chip removal for grinding chips during grinding, and can

accommodate coolant, which is helpful for the dissipation of grinding heat. In

order to meet some special processing requirements, some fillers, such as

sulfur and paraffin, can also be impregnated in the pores to improve the

performance of the abrasive tool. This kind of filler, is also known as the

fourth element of the abrasive.

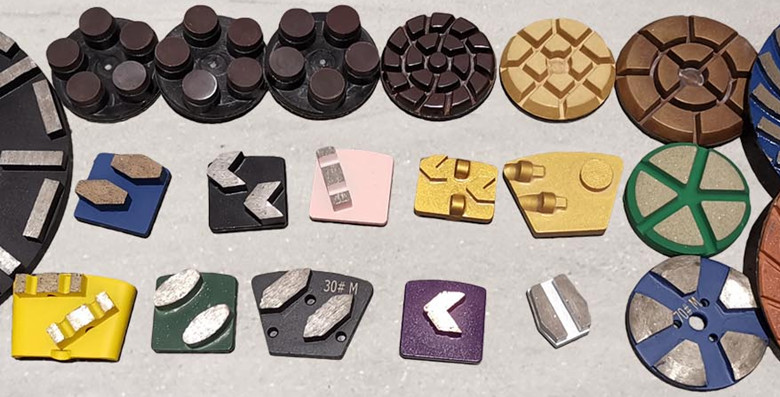

DTS Diamond Tools is a professional manufacturer of diamond tools for

concrete or stone floor grinding and polishing, we have supplied many different

kinds of diamond tools for many customers, such as Scanmaskin tools,

Lavina tools, Klindex tools, Husqvarna tools, HTC tools etc. Welcome

to consult for our products by clicking pictures to get into our official web

if you are interested.

- Company Info

- Feedback

- Customer Reviews

- About Us

- Contact Us

- Blog

- Help Center

- User Center

- Forget Password

- My Orders

- Tracking Order

- My Account

- Register