Stone Processing: Process Selection for Diamond Saw Blades2022-10-21

Hydraulic balance and compensation of CNC floor boring and milling machines Machine tool industry's demand for bearings New machine tools with international advanced level Selection of cutting amount for indexable shallow hole drilling off-line in Kunming New functions and features of PowerMILL7.0 Zigzag on CNC lathes Deformation research of machining large edge inclination angle cutting Application of mechanical processing method in computer three-dimensional drawing CNC lathe machining source program of disc parts 1 Application of tool compensation in CNC machining Carbide gun drill Introduction of key tool management for industrialization of functional components -Innovative idea to save production cost Transistor amplifier structure UG file name naming suggestion Erzhong Group won "China Patent Excellence Award Ultra-high temperature resistant forging die material successfully developed in Taiwan Perfect combination of PLC and motion control 4-axis motion with PLC function Controller A is also afraid of intelligent CNC system: a new trend in the development of CNC technology.

1. Selection of diamond particle size

When the diamond particle size is coarse and single particle size, the saw blade head is sharp and the sawing efficiency is high, but the bending strength of diamond agglomeration decreases; when the diamond particle size is fine or coarse and fine particle size is mixed, the saw blade head has high durability, but less efficient. Considering the above factors, it is more appropriate to choose the diamond particle size as 50/60 mesh. Selection of diamond particle size When the diamond particle size is coarse and single particle size, the saw blade head is sharp and the sawing efficiency is high, but the bending strength of diamond agglomeration decreases; when the diamond particle size is fine or coarse and fine particle size is mixed, the saw blade head is durable. high degree, but low efficiency. Considering the above factors, it is more appropriate to choose the diamond particle size as 50/60 mesh.

2. Selection of diamond distribution concentration

Within a certain range, when the diamond concentration changes from low to high, the sharpness and sawing efficiency of the saw blade gradually decline, while the service life gradually extends; but if the concentration is too high, the saw blade will become dull. With low concentration and coarse particle size, the efficiency will be improved. Taking advantage of the different functions of each part of the cutter head during sawing, different concentrations are used (that is, in a three-layer or multi-layer structure, a lower concentration can be used for the middle layer), and the cutter head forms an intermediate groove during the sawing process. It is beneficial to prevent the saw blade from swaying, thereby improving the quality of stone processing.

3. Choice of diamond strength

The strength of diamond is an important indicator to ensure cutting performance. If the strength is too high, the crystal will not be easily broken, the abrasive particles will be polished during use, and the sharpness will be reduced, resulting in the deterioration of the tool performance; when the diamond strength is not enough, it will be easily broken after being impacted, and it is difficult to undertake the heavy duty of cutting. Therefore, the strength should be selected between 130 and 140N.

4. Selection of binder phase

The

performance of the saw blade does not depend only on the diamond, but on the

overall performance of the composite material of the cutter head formed by the

proper combination of diamond and binder. For soft stones such as marble, the

mechanical properties of the cutter head are required to be relatively low, and

copper-based binders can be used. However, the copper-based binder has low

sintering temperature, low strength and hardness, high toughness, and low

bonding strength with diamond. When adding tungsten carbide (WC), use WC or W2C

as the skeleton metal, with an appropriate amount of cobalt to improve

strength, hardness and bonding characteristics, and add a small amount of metals

such as Cu, Sn, Zn, etc. with low melting point and low hardness for bonding mutually.

The particle size of the main additive component should be finer than 200 mesh,

and the particle size of the additive component should be finer than 300 mesh.

5. Selection of sintering process

With the

increase of temperature, the degree of densification of the matrix increases,

and the flexural strength also increases, and with the extension of the holding

time, the flexural strength of the blank matrix and diamond agglomerates first

increases and then decreases. Sintering at 800°C for 120s to meet the

performance requirements.

As a new

material, concrete moisturizing and curing film is widely used in various

fields of highway, railway, water conservancy and other engineering

construction, and plays an increasingly important role in the prevention of

concrete quality problems.

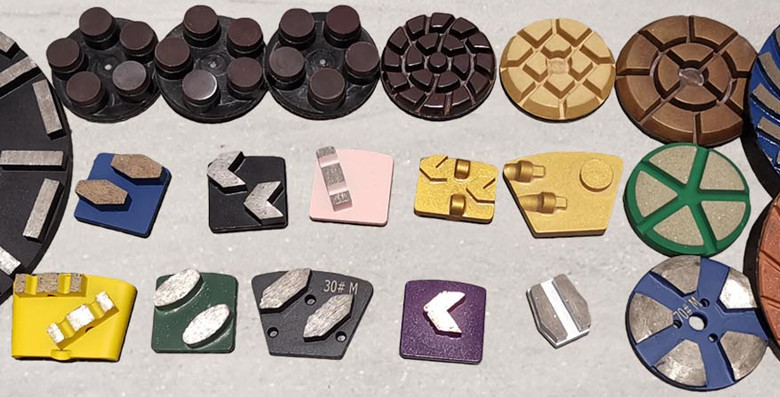

DTS

Diamond Tools is a professional manufacturer of diamond tools for concrete or

stone floor grinding and polishing, we have supplied many different kinds of

diamond tools for many customers, such as Scanmaskin tools, Lavina tools,

Klindex tools, Husqvarna tools, HTC tools etc. Welcome to consult for our

products by clicking pictures to get into our official web if you are

interested.

- Company Info

- Feedback

- Customer Reviews

- About Us

- Contact Us

- Blog

- Help Center

- User Center

- Forget Password

- My Orders

- Tracking Order

- My Account

- Register